Copyright

©The Author(s) 2022.

World J Orthop. Jun 18, 2022; 13(6): 578-586

Published online Jun 18, 2022. doi: 10.5312/wjo.v13.i6.578

Published online Jun 18, 2022. doi: 10.5312/wjo.v13.i6.578

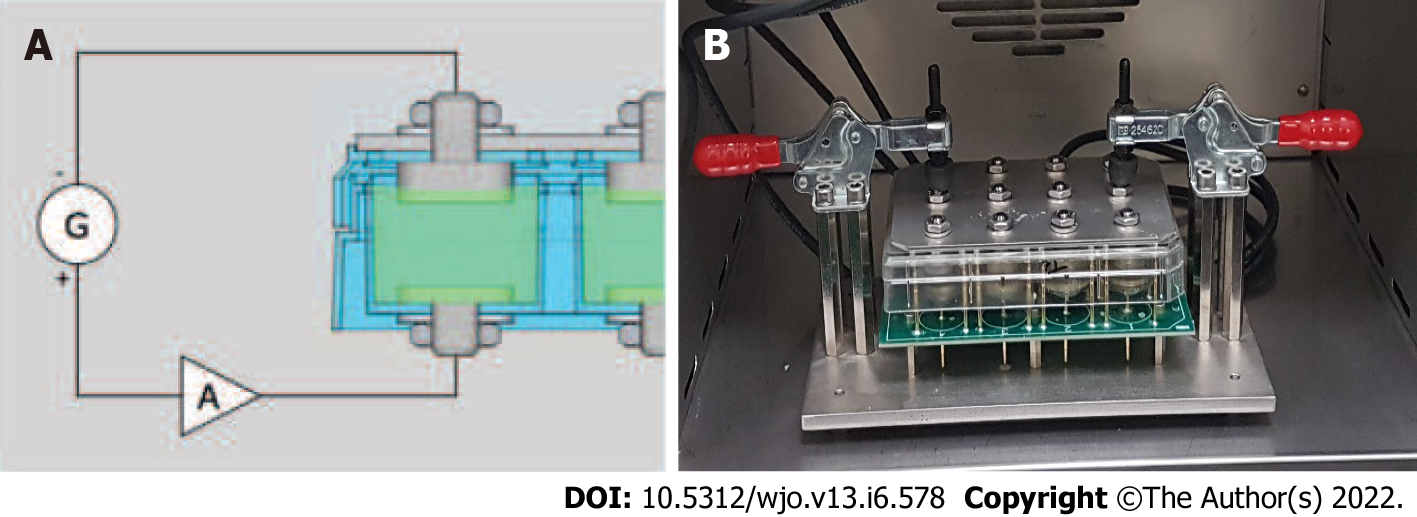

Figure 1 Design of the 12-well culture plate.

A: The connection to the generator, the amplifier, and both electrodes in one of the wells of the plate. The lower electrode acted as a cathode, and the upper electrode acted as an anode; B: Photograph of the function generator with four separate connections to allow four different trials to be performed simultaneously. There are three rows of wells on the culture plate allowing tests to be triplicated.

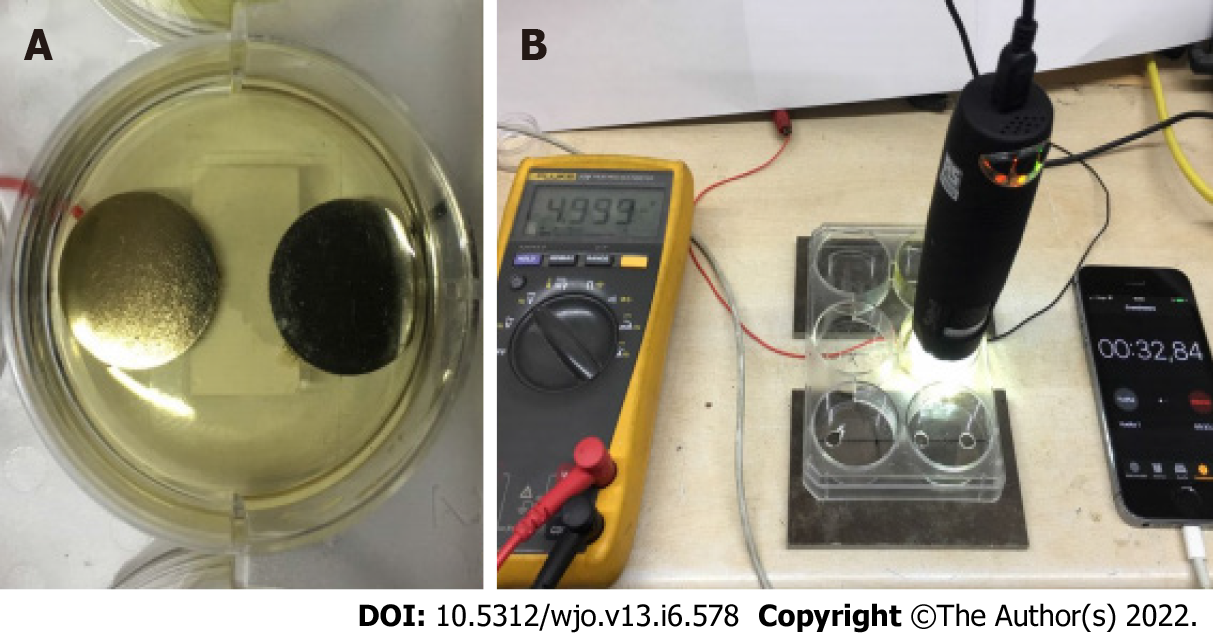

Figure 2 Electrical field application without bacteria.

A: Initial setup of the titanium disks; B: Microscope used to visualize titanium oxidation and bubble formation.

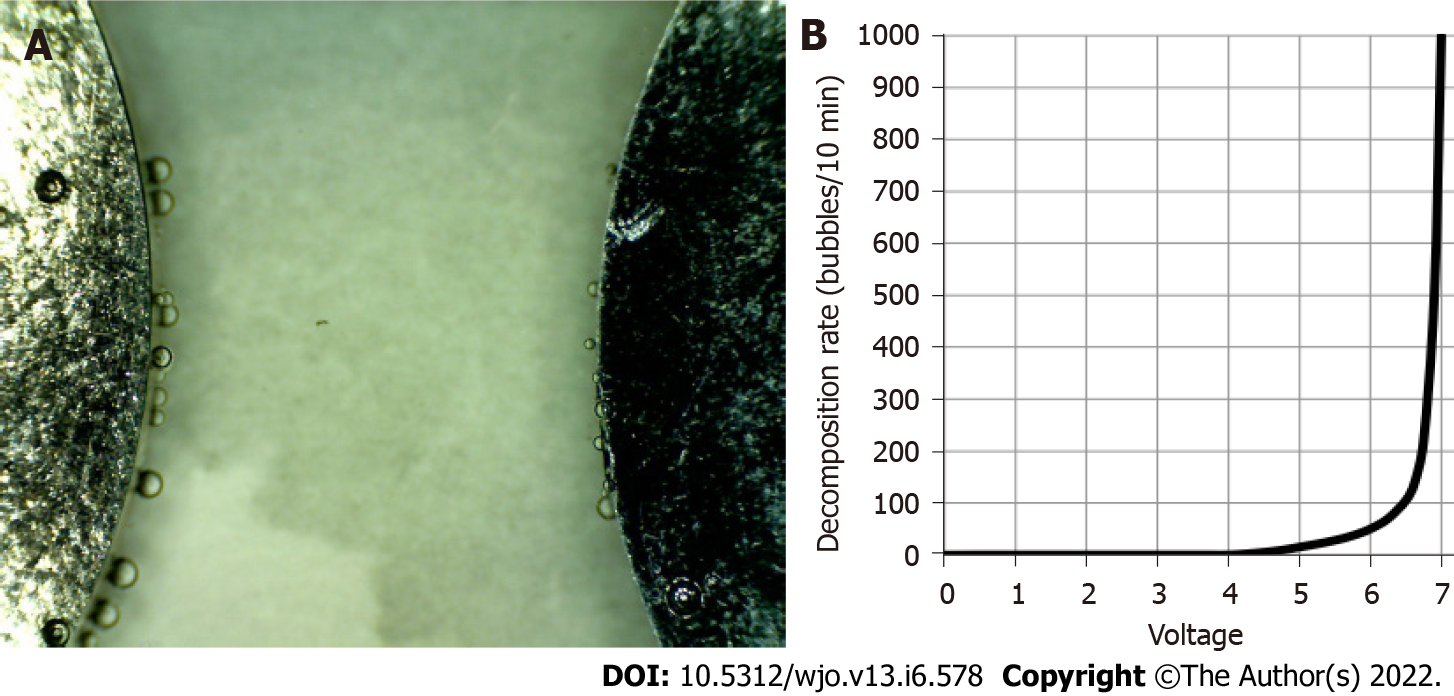

Figure 3 Microbubble formation test and results.

A: Microbubble formation at the cathode using a 7 V current; B: Bubble rate formation on the X-axis compared to voltage. Exponential formation of bubbles after 5V.

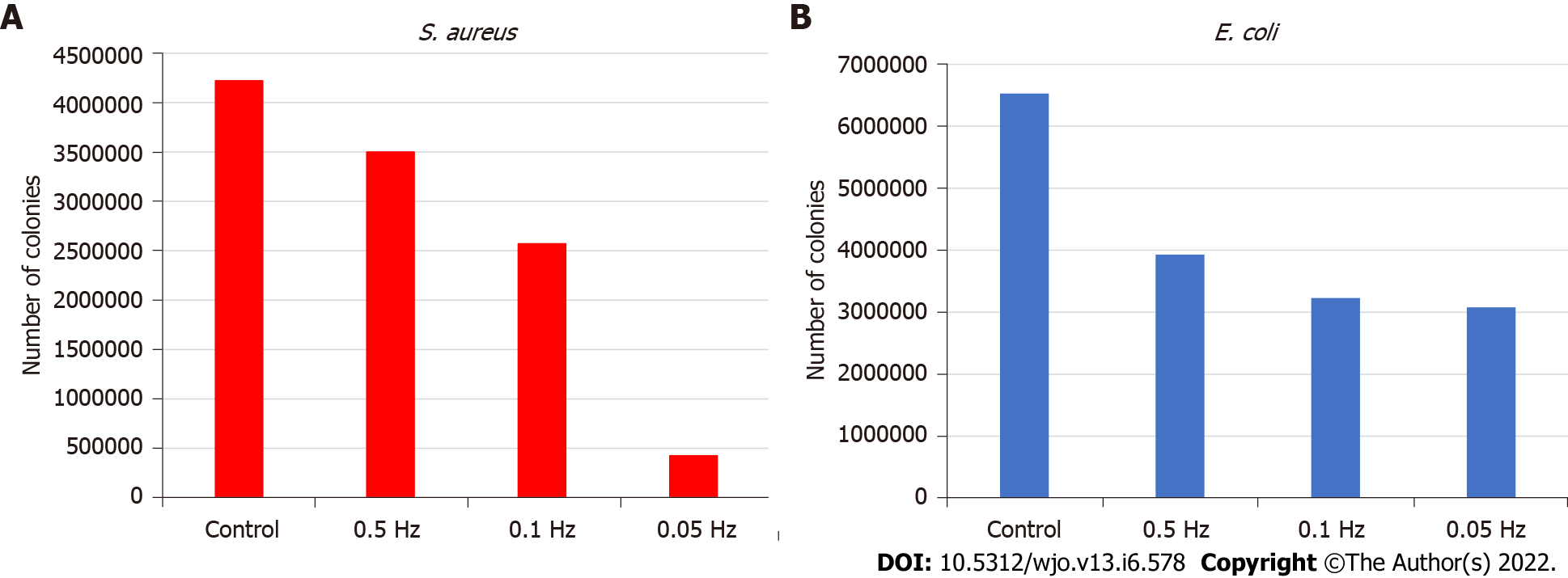

Figure 4 Results for colony-forming units.

A: Results for colony-forming units of Staphylococcus aureus for the studied conditions; B: Results for colony-forming units of Escherichia coli for the studied conditions. S. aureus: Staphylococcus aureus; E. coli: Escherichia coli.

Figure 5 Bacteria inside the lumps formed by electrocoagulation of the medium.

Figure 6 Anodizing of the titanium surfaces.

- Citation: Bernaus M, Guillem-Marti J, Bermúdez-Castel A, Calero JA, Torres D, Veloso M, Font-Vizcarra L. Reducing bacterial adhesion to titanium surfaces using low intensity alternating electrical pulses. World J Orthop 2022; 13(6): 578-586

- URL: https://www.wjgnet.com/2218-5836/full/v13/i6/578.htm

- DOI: https://dx.doi.org/10.5312/wjo.v13.i6.578