Copyright

©2013 Baishideng Publishing Group Co.

World J Gastroenterol. Sep 21, 2013; 19(35): 5943-5946

Published online Sep 21, 2013. doi: 10.3748/wjg.v19.i35.5943

Published online Sep 21, 2013. doi: 10.3748/wjg.v19.i35.5943

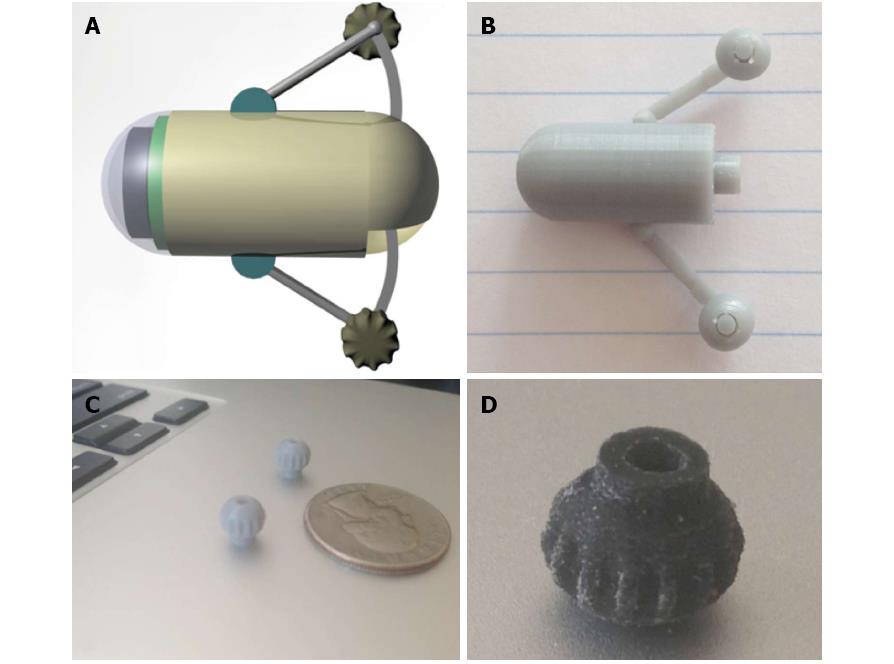

Figure 1 Capsule odometer,conceptual design and its three-dimensional printing realisation.

A: Conceptual design[10] of a capsule endoscope (herein called ODOcaps) with protruding wheels attached to a spring-mechanism; B: Three-dimensional printing technology used to build a capsule prototype; C: Wheels were initially produced with UV Curable Acrylic Plastic; D: Wheels later made of a synthetic resilient, textile-like material (TPU 92A-1).

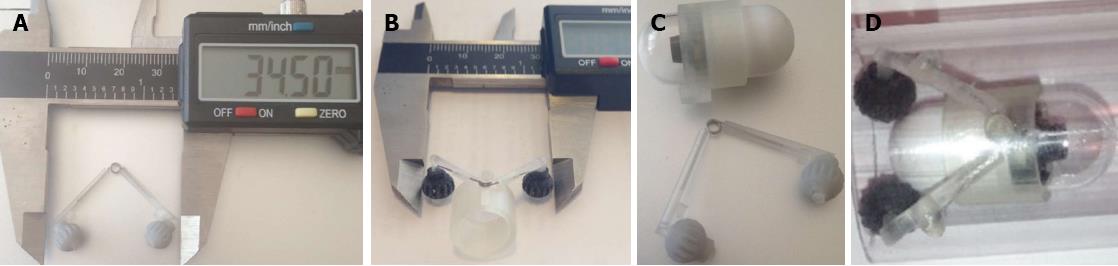

Figure 2 In vitro experiment.

A: Wheels inserted in three-dimensional printed, L-shaped miniature tubes. Tubes along with the wheels attached to a spring; B: stainless steel torsion spring with 90° deflection and 0.093 inch pounds torque from Associated Spring Raymond allows extension/retraction of the wheels; C: Three-dimensional printed ring (11.5 mm in diameter made of UV Curable Acrylic Plastic on a demo PillCam® SB2); D: Inserted into one end of a translucent tube and pulled through by a silk string.

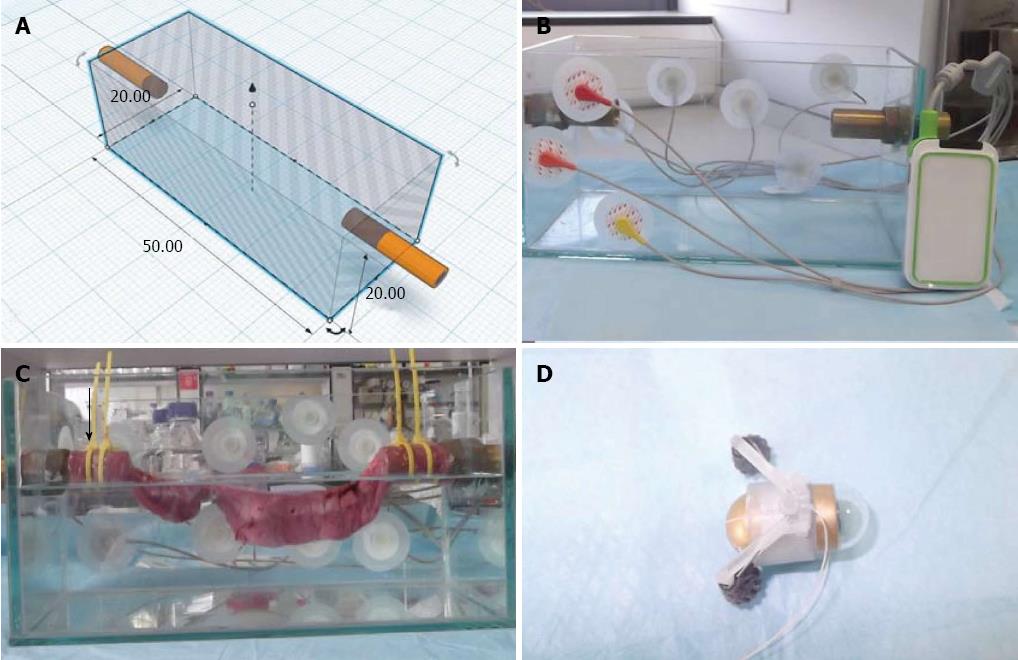

Figure 3 In vivo experiment.

A and B: Glass tank (50 cm × 20 cm × 20 cm) with fix points for the intestine (metal tubes) and entry points for the capsule device, C: Standard simulated intestinal environment created by mounting 32 cm long, freshly harvested porcine small-intestine to both ends of a fluid-filled tank (arrow); D: Capsule device (assembled ring with wheels on spring on a MiroCam®) was inserted into the suspended bowel via one of the metal tubes.

- Citation: Karargyris A, Koulaouzidis A. Capsule-odometer: A concept to improve accurate lesion localisation. World J Gastroenterol 2013; 19(35): 5943-5946

- URL: https://www.wjgnet.com/1007-9327/full/v19/i35/5943.htm

- DOI: https://dx.doi.org/10.3748/wjg.v19.i35.5943